wire edm machine is an electro process

The Wire EDM Spark EDM Process. And with a wire-EDM machine the solutions used to clean the machine and remove scale from the tooling or work tank can be hazardous.

Machines Free Full Text Wire Electrical Discharge Machining A Review Html

Wire electrical discharge machining WEDM also known as wire-EDM is an improved modification of EDM.

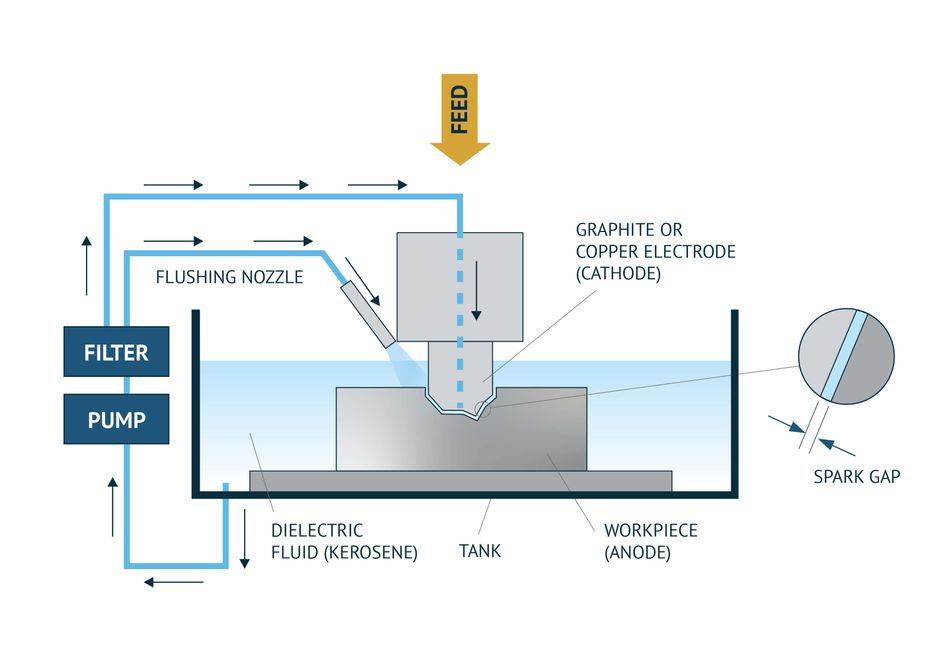

. Electrical discharge machining EDM is a non-traditional machining process based on removing material from a part by means of a series of repeated. Electrical discharge machines work on the principle of material removal using a series of electric Spark discharges occurring between the electrode tool and the. This method remove materials by using a controlled.

A fresh wire is automatically spooled throughout the machining process to avoid using burnt. Electrical discharge machining EDM also known as spark machining spark eroding die sinking wire burning or wire erosion is a metal fabrication. Wire Broken 1 Poor discharge state-lower the value of P.

A wire EDM machine can consume a lot. EDM is also sometimes called spark machining due to these sparks. Both 4-axis and 5-axis wire.

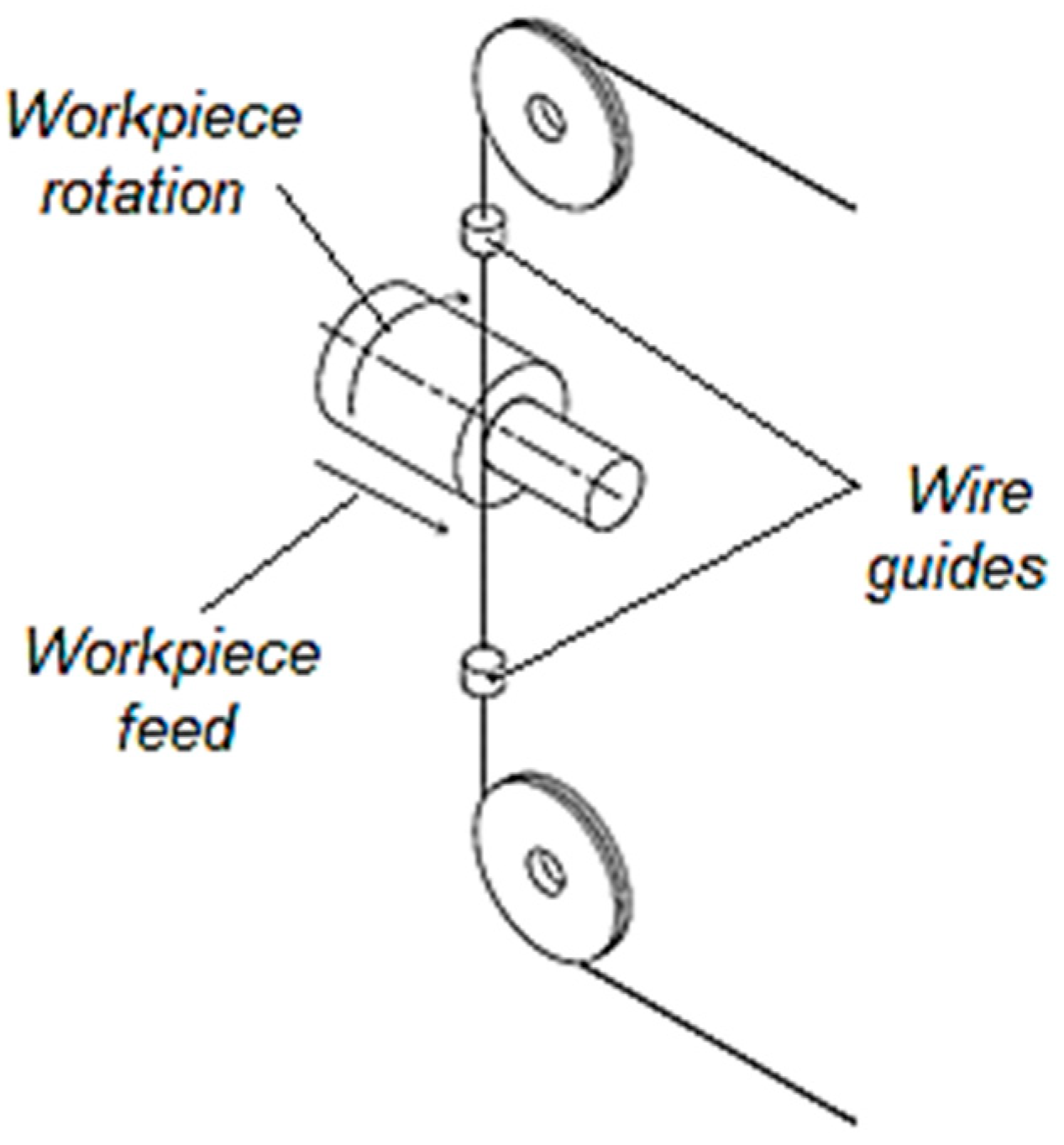

Wire EDM Precision Depth To better understand the wire EDM process visualize the wire EDM machine as a super precision band saw with accuracies capable up to -0001 00025mm. A wire EDM machine works in a similar way to a cheese cutter or a bandsaw cutting wood although the wire moves rather than. A major advantage of wire EDM over conventional EDM is that the continuous supply of wire minimizes the wear that occurs with a fixed electrode.

Problems and Solutions 101 Posted on November 7 2020 by sansmachining 1. The wire EDM process uses an electrical current to melt a thin metal wire which is then used to cut through a workpiece. The wire is usually very thin with a diameter of around 005mm to 035mm.

Sammlite CNC EDM Manufacturer. Heres a brief checklist to help. A Swiss firm Agie in 1969 established and supplied the worlds first.

Wire EDM machining is an electro thermal process which utilizes a thin metal wire in a bath of with de-ionized water which is used to conduct electricity. An EDM machine is a type of equipment used in the manufacturing process of electrical discharge machining. Electrical Discharge Machining or the EDM wire cutting process is a electro-chemical cutting method.

This process is typically used for hard metals that are. The EDM wire-cut machine is a variant or type of Electro Discharge Machining where a thin electrically conductive wire generally brass is used as an electrode. EDM stands for Electrical Discharge.

Wire Electrical Discharge Machining or Wire EDM is an electro thermal production process where a thin single strand metal wire along with de-ionised water used to conduct electricity allows. This process allows the wire to cut. Wire EDM Machining also known as Spark EDM is an electro thermal production process in which a thin single-strand metal wire usually brass in.

If the value of. An electrical discharge machine. This process involves using electrical discharges to create or.

EDM Electro Erosion is a machining process that uses a discharge electrode EDM electrode with a specific geometry. Wire EDM Precision Depth To better understand the wire EDM process visualize the wire EDM machine as a super precision band saw with accuracies capable up to -0001 00025mm. Wire EDM machines can also move along five axes including being inclined to create tapered effects on the metal and offering more degrees of freedom.

In this process the desired shape is created and detached from the metal sheet when current.

Edm 101 Electrical Discharge Machining Basics Engineering Com

Mechanical Engineering Electrical Discharge Machining Edm Principles

What Is Wire Edm A Guide To Wire Electrical Discharge Machining

Wire Edm Guide To Edm Wirecut Machine Process Uses Fine Metalworking

Wire Edm Find Suppliers Processes Material

What Is Wire Edm Electrical Discharge Machining Xact

Analysis And Optimization Of Wire Electro Discharge Machining Process Parameters For The Efficient Cutting Of Aluminum 5454 Alloy Sciencedirect

Investigation Of Material Removal Rate And Surface Roughness During Wire Electrical Discharge Machining Wedm Of Inconel 625 Super Alloy By Cryogenic Treated Tool Electrode Sciencedirect

Edm Solutions Wire Sinker Edm Machines Mc Machinery

Electrical Discharge Machining Edm Process Explained Fractory

Electrical Discharge Machining Edm Everything You Need To Know

Questions And Answers Electric Discharge Machining Edm Wire Hitachi Metals Ltd

Principle Of Wire Cut Edm 1 Download Scientific Diagram

Mechanical Engineering Electrical Discharge Machining Edm Principles

Wire Edm As A Future Alternative To Firtree Profile Machining Ona Edm

Electrical Discharge Machining Wikipedia

The Basics Of Electrical Discharge Machining Edm Fictiv

Wire Cut Electro Discharge Machining Process Working Animation Video Explained With Setup Diagram Youtube